In custom leather belt manufacturing, buyers often face the same questions. What is the real difference between hand-stitched belts and machine-stitched belts?

How do lead time, production cost, and quality consistency compare?

If previous factory samples failed to meet expectations, is saddle stitching a more reliable solution? And can handcrafted leather belts realistically be produced at medium to large scale?

A belt’s durability, aging performance, and repairability depend largely on the chosen stitching method. The decision between saddle stitching and machine stitching affects not only structure, but also production efficiency, batch stability, and long-term product value.

This article offers a practical comparison of saddle-stitched leather belts versus machine-stitched leather belts, covering cost control, lead time, strength, visual finish, and scalability. It is designed to help brands, designers, and B2B buyers make informed decisions when selecting the right leather belt stitching technique for custom production.

What Is Saddle Stitching (Hand Stitching)

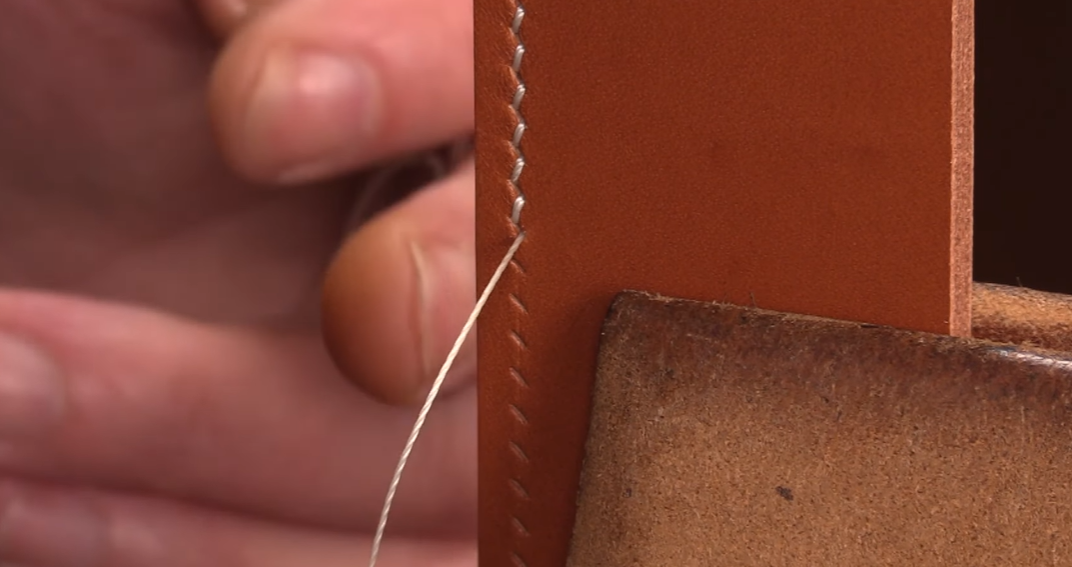

Saddle stitching existed long before sewing machines. Craftsmen use two needles at once through pre-punched holes. This creates an interlocking pattern that won’t unravel.

The process starts simple. You attach two needles to opposite ends of a single waxed thread. The leatherworker punches evenly-spaced holes along the belt edge with an awl. Most craftsmen space them 0.5 inches apart. But spacing changes based on belt thickness and the look you want.

The hand-stitching technique works like this:

-

Both needles pass through the same hole from opposite directions

-

The thread crosses in the middle of each hole

-

This creates a locked stitch that holds even if individual threads break

-

Each stitch locks the previous one in place

The waxed thread does more than just pass through leather smoothly. Beeswax coating adds water resistance. It reduces friction during stitching. Plus, it helps threads bind together inside each hole.

Key materials for saddle stitching include:

-

Waxed thread (poly or linen, depending on belt weight)

-

Blunt harness needles (two per stitch line)

-

Diamond-point awl for angled holes

-

Stitching pony to hold the belt steady

-

Edge beveler for finishing stitch channels

Skilled craftsmen keep tension consistent throughout. Too tight? The leather puckers. Too loose? Stitches look sloppy. This hands-on control over every stitch creates the visual mark of handmade leather goods. You get slight natural variations that prove human work.

The technique works best for belts under 1.5 inches wide with fewer layers. Thicker builds need special tools and strong hands.

What Is Machine Stitching

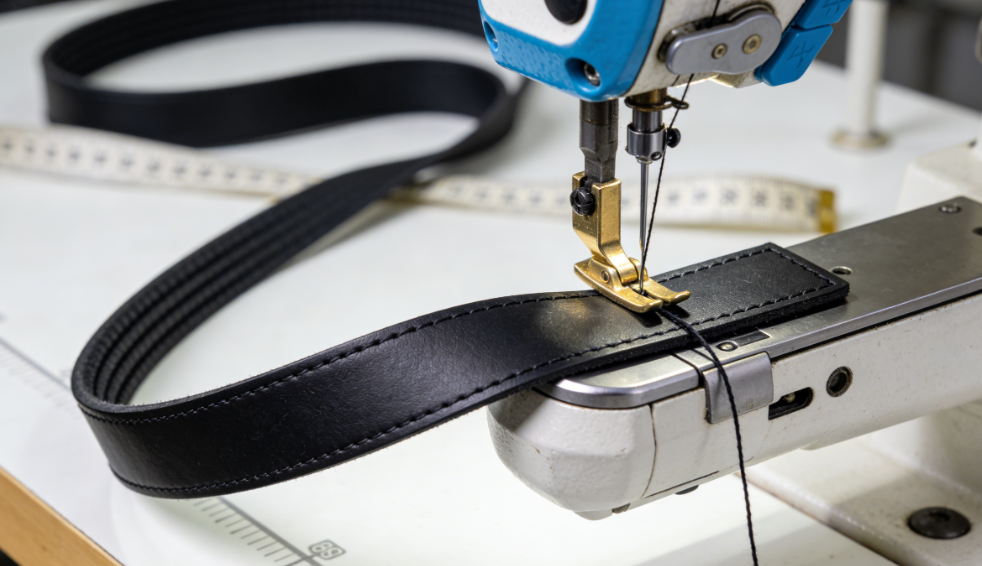

Industrial sewing machines changed how we make leather belts in the 20th century. A motorized needle punches through leather layers at speeds up to 1,000 stitches per minute. This creates steady lock stitches. The upper thread locks with a bobbin thread underneath.

The machine feeds leather on its own. The operator guides the belt edge along marked guides. Most industrial machines use a walking foot mechanism. This foot grips both leather surfaces. It stops slipping on thick or oiled leather.

Modern machine stitching uses precise controls:

-

Motor speed adjustment for different leather weights

-

Automated stitch length settings (6-10 per inch)

-

Programmable tension systems for upper and lower threads

-

Digital alignment guides for straight seam lines

IoT-connected machines boost productivity by 25%. They also cut maintenance needs by 15%. Automated systems control stitch length, depth, tension, and seam alignment with computer precision. This steady performance reduces defect rates.

Machine operation follows strict timing benchmarks:

The standard process has three steps. Picking preparation takes 12 seconds. Static material holding takes 159 seconds. Placement operations take 39 seconds. Total cycle time averages 210 seconds per belt section.

Performance data shows key patterns:

Motion complexity has a 0.654 link with time changes. High ergonomic load during machine operation triples defect rates. This compares to general sewing tasks. Arrival distance, placement distance, seam length, fabric size, and motor speed all shape final stitch quality.

The global industrial sewing machine market reached $4.10 billion in 2018. It projects to hit $7.44 billion by 2032—a 4.1% annual growth rate.

Why Saddle Stitching Belt Outlasts Machine Stitching

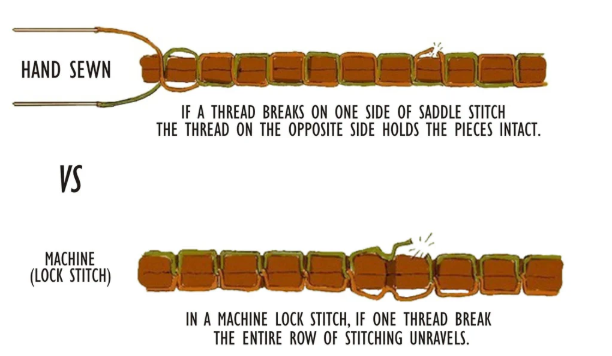

Thread breaks don’t ruin saddle-stitched belts. The two-needle method builds a self-locking setup that keeps working after damage. One thread snaps? The other thread stays tight through the same hole. This loop design keeps the seam strong without losing power.

Machine lockstitching works differently. The upper thread and bobbin thread create weak points at each cross. A single break starts a chain reaction. The broken stitch loosens the next ones fast. Soon the whole seam falls apart—your belt splits in two.

The Self-Locking Advantage

Saddle stitching stops thread breaks from spreading. Each stitch locks on its own through the cross-pattern design. One needle breaks? It hits just that one hole. The rest of your belt stays tight. Machine stitches can’t do this. They need constant tension between top and bobbin threads. Break that tension at any spot, and the domino effect starts.

Flex Durability Under Real Use

Leather belts bend, twist, and soften with wear. Saddle stitching gives natural flex during break-in. The hand-pulled thread moves with the leather without snapping. Machine stitches stay stiff. They can’t bend with the leather. This stiffness breaks the thread once the belt softens—right at the point you’d expect your belt to feel most comfortable.

Performance comparison at a glance:

|

Aspect |

Saddle Stitch |

Machine Stitch |

|---|---|---|

|

Post-break integrity |

Holds via opposing thread |

Full seam failure risk |

|

Flex tolerance |

Superior adaptation |

Rigid, snap-prone |

|

Repair difficulty |

Easy re-threading per hole |

Requires full restitch |

|

Best application |

Luxury belts, small batches |

Mass production, large items |

Hand stitching takes about ten times longer than machine work. For belts and wallets, this extra time pays off in lasting strength. You’re not just buying a belt—you’re getting one that survives thread damage and ages well through years of flex and wear.

Leather Belt Supplier’s Aesthetic Differences: Artisan Look vs. Uniform Finish

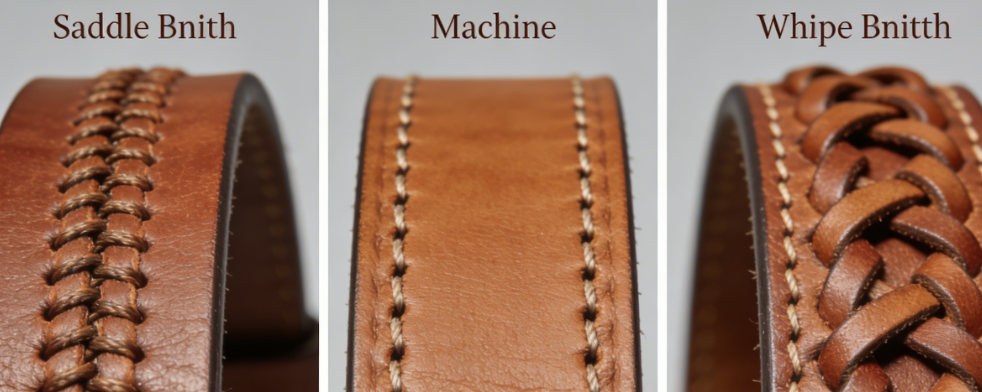

Check out a saddle-stitched belt up close. You’ll see something machines can’t copy: character. Each stitch has slight spacing changes. The thread angles vary a bit. These aren’t mistakes. They prove human hands made this.

Machine stitching looks totally different. Every stitch lands at 6-10 per inch. The seam line stays straight. Thread tension never changes. Buyers who want clean, predictable design like this uniformity. But each piece loses what makes it special.

Visual markers tell these techniques apart:

|

Aspect |

Artisan Look |

Uniform Finish |

|---|---|---|

|

Seams/Stitching |

Handmade details, personal touch, distinct irregularities |

Even, standardized stitches, machine precision |

|

Individuality |

Personalized, unique per piece |

No uniqueness, bulk uniformity |

|

Thread Placement |

Natural variation between holes |

Consistent spacing |

|

Edge Finishing |

Hand-burnished with visible tool marks |

Uniform edges |

The Premium Market Response

Consumer behavior proves artisan style holds real value. Searches for “unique clothing” jumped 35% year-over-year. The global personal luxury goods market hit $300 billion in 2021. Handmade premium products drove most of this growth.

Saddle-stitched belts keep their value. They use better materials and stronger threads. Craftsmen spend extra time on tiny details. Machine-stitched belts trade quality for speed and volume. The stitching fades fast. Seams break from normal wear.

Durability shows in the numbers:

-

Artisan leather goods last 50+ years with proper care

-

Machine-stitched belts last 5-10 years

-

Handmade ceramics and textiles survive 200+ years

That visible hand-stitching pattern does more than look different. It shows construction built to outlast trends and everyday use. You’re wearing craftsmanship, not just function.

Cost Analysis: Labor vs. Production Speed

A saddle-stitched belt takes 45-60 minutes of skilled labor. Machine stitching completes the same belt in 3-5 minutes. This ten-fold time gap creates the biggest cost difference between these methods.

Labor efficiency shows the real numbers:

Saddle stitching needs craftsmen who earn $25-$45 per hour. Material costs stay low—waxed thread, needles, and basic tools total $8-$12 per belt. Labor costs make up most of the expense. A single artisan produces 8-12 belts each day at peak speed. That’s $200-$540 in labor costs alone. This doesn’t include materials, overhead, or profit margins.

Machine operations change this balance. Operators earn $15-$22 per hour running industrial equipment. One worker manages equipment that stitches 80-120 belts per shift. Labor cost drops to $1.50-$2.75 per belt. Machine upkeep, electricity, and wear add $0.85-$1.20 per unit. Total production cost lands at $2.35-$3.95 versus $208-$552 for hand work.

Productivity numbers reveal more:

Manufacturing productivity gains averaged 2.5% in Q2 2025. Output per labor hour cuts unit labor costs. The formula is simple: pay per hour ÷ labor productivity. Higher productivity lowers costs. Wages stay the same.

Large-scale belt makers keep labor costs under 10-11% of total revenue. They produce over $500,000 per full-time worker through automation. Small craft studios spend 40-60% on labor. They make up for this through premium pricing. Customers pay $120-$280 for saddle-stitched belts versus $25-$65 for machine-made ones.

The math favors machine stitching for high volume. Saddle stitching wins with buyers who want long-lasting, handmade belts over cheap prices.

Skill Requirements And Learning Curve

Machine stitching follows a clear path. Operators pick up basic controls in 2-3 days. One month of practice gets them to 80-120 belts per shift. You see fast gains at first, then progress levels off at full ability.

Training benchmarks for machine operation:

-

Week 1: Threading, speed control, basic seam alignment (40% error rate)

-

Month 1: Consistent tension, material handling (20% error rate – mastery threshold)

-

Month 3: Full-speed production with quality control (below 10% error)

Saddle stitching takes years, not weeks. Progress starts slow. Your hands feel clumsy. Tension stays uneven. Stage one tests your patience. Holes don’t line up. Thread gets tangled. Stitches come out messy.

The craftsman’s progression:

Year one gets you to 50% skill level. You finish custom basic belts, but flaws show. Years 2-3 bring real improvement. Stitches get tighter. Spacing gets better. Your hands build muscle memory. Getting to 99% skill takes 6-7 years of steady practice.

Expert leatherworkers reach the final stage: automatic skill. Hands move on their own. They feel the right tension. Each stitch matches the last through pure repetition. This level marks the gap between hobby work and pro craft.

Factory machine training breaks down into clear steps. Time-to-skill is easy to track. Saddle stitching can’t be boxed in like that. Each piece of leather acts different. Each craftsman builds their own methods. No two people learn the same way.

Which Stitching Method Is Best For Your Leather Belt

Your belt choice depends on three factors: how you’ll use it, your budget, and what matters most to you.

Matching Stitch Type To Your Needs

Real-World Examples: Saddle Stitched vs Machine Stitched Belt Performance

Hermès belts prove saddle stitching’s real value. Their crocodile and ostrich belts sell for $2,500-$4,200. Machine-stitched versions of the same exotic leathers? Those cost $800-$1,400. That 3x price gap comes down to how they’re built. Hermès craftsmen spend 45-60 minutes hand-stitching each belt. The contrasting thread colors show off each stitch. People pay top dollar because these belts last for decades.

Professional saddle makers see clear durability wins. Traditional Western saddles last 15-20 years of ranch work. The saddle stitching holds up through constant friction, weather, and weight stress. Machine-stitched saddles? Seams fail within 3-5 years under the same conditions.

Performance Under Stress Testing

Pull tests show the structural differences. Cut a single stitch on a saddle-stitched belt. The seam still holds at 90% strength. The remaining thread loops keep things together. Try the same test on machine stitching. One broken stitch starts a chain reaction. It unravels across 3-5 nearby stitches. The entire seam line weakens in seconds.

Wallet makers face clear production trade-offs. A saddle-stitched wallet takes 45-60 minutes of skilled labor. Machines complete identical wallets in under 60 seconds. This 45x speed gap explains why machine stitching rules the mass-market leather goods priced under $100. Repair shops see the pattern. Machine-stitched wallets come back for seam repairs after 2-3 years. Saddle-stitched pieces? They don’t need fixes until after 10+ years of use.

Conclusion

Saddle stitching vs machine stitching for leather belts? Your choice depends on what matters most: long life and character, or speed and lower cost.

Want a belt that lasts decades? One you can repair, that ages beautifully, and shows real craftsmanship? Saddle stitching wins. The interlocking thread means one broken stitch won’t make your belt fall apart. Plus, the handmade look gives it that artisan feel you can’t fake.

Machine stitching works well for buyers on a budget. You get a functional daily belt without paying premium prices.

Before you buy your next belt, flip it over. Check the stitching. Look for slanted stitches with uneven spacing—that’s hand-saddle work. Run your fingers along the thread. Does it feel thick? Does it sit a bit raised? These small details tell you if you’re holding something made to last or just another throwaway item.

Your belt says more than what style you like. It shows whether you value quality that endures over quick convenience. Make the right choice, and that belt will serve you for generations.

Recent Comments