Finding the right partner for custom PU handbags can make or break your fashion brand.

China has thousands of factories spread across its production hubs. Finding quality suppliers is tough. You need consistent craft, good pricing, and clear communication.

Launching a new handbag line? Or growing your current collection? You need makers who know global quality standards. They must adapt to your unique designs.

We’ve done the hard work for you. Here are China’s top 5 custom PU handbag makers. Each one is checked for production size, custom options, and proven success with global buyers.

You’ll get more than just names. Learn the key factors that set great makers apart from average ones. Plus, get clear steps to check credentials and start partnerships with confidence.

|

Factory Name |

Production Scale |

MOQ |

Lead Time |

Certifications/Compliance |

Key Features |

Best For |

|---|---|---|---|---|---|---|

|

Guangzhou Xinxin Leather Goods Co., Ltd. |

500,000+ units/month |

300 pieces |

25-35 days |

BSCI, ISO 9001, REACH color fastness |

Mid-to-high-end PU handbags for Europe and North America Full ODM from sketch to 3D prototype in 7 days |

Brands needing tricky hardware (magnetic closures, branded zippers, metal logo plates) |

|

Dongguan Meiya Fashion Accessories Factory |

300,000 units/month |

500 pieces |

30-40 days |

CA Prop 65, Eco/Green focus (no phthalates, water-based coatings) |

Three lines for vegan leather handbags Worked with 40+ global brands since 2012 |

Green brands that need CA Prop 65 compliance and clear material sourcing |

|

Shenzhen Huaxin Bag Manufacturing Ltd. |

200,000 units/month |

200 pieces |

20-30 days |

– |

Flex production model (small startups to big retailers) Lowest MOQs among top makers Three-layer quality control |

New brands with limited budgets wanting top quality |

|

Yiwu Liansheng Leather Products Co., Ltd. |

400,000 units/month |

1,000 pieces |

35-45 days |

– |

Located in Yiwu, rapid trend designs Full chain from PU fabric weaving to finished bags |

Big-volume buyers needing competitive prices and broad design choices |

|

Quanzhou Jiali Handbag Co., Ltd. |

250,000 units/month |

500 pieces |

28-38 days |

– |

Hand-polished edges, double-stitch real leather method Client retention rate: 85% |

Premium brands selling to department stores and boutiques needing perfect finishing |

Match what you need with what each maker does best. Xinxin handles tricky hardware. Meiya does green materials. Huaxin fits startups. Liansheng gives you cost savings. Jiali brings luxury quality. Each one lets you order samples before you commit to big orders.

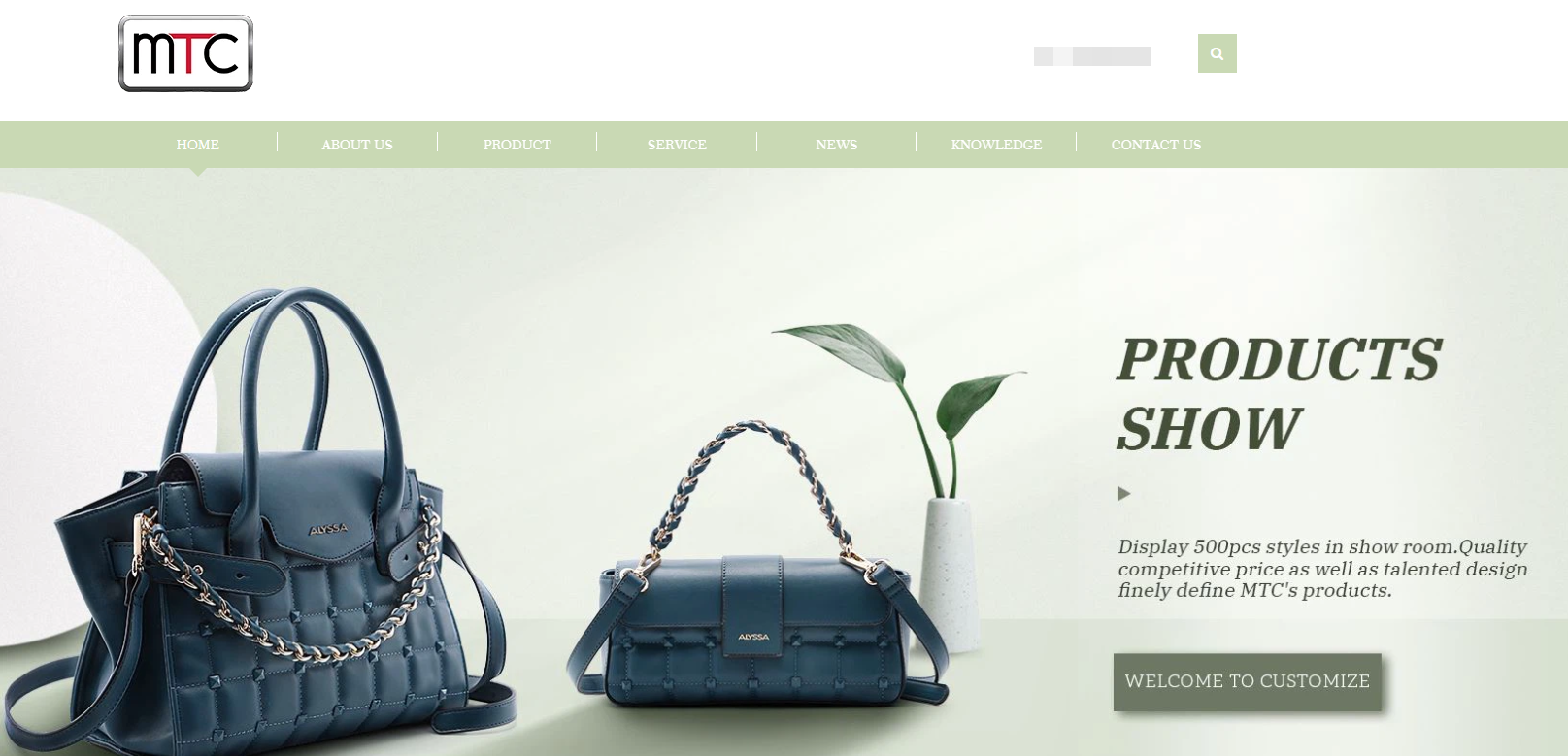

Guangzhou MTC Bags Co., Ltd.

Production Scale: Making bags since 2007 | MOQ: 300+ pieces | Location: Huadu District, Guangzhou

MTC Bags has over 12 years making custom PU handbags. Their Huadu factory is in Guangzhou’s leather goods district. Raw material suppliers are close by. Logistics networks are nearby too. This keeps costs down. Plus, you get faster production times.

Export Track Record: Trade data shows strong global sales. The company shipped 253 verified orders through Trademo. U.S. Customs shows 386 shipments from July 2018 to December 2025. The United States is their main market. They know Western quality standards. They understand what buyers expect.

Best For: Global brands selling to North America. Their large U.S. export volume shows they know the process. They handle customs papers well. Shipping logistics run smooth. Compliance requirements are no problem. You work with a maker who ships hundreds of containers to your market already.

Verification Tip: Ask for recent U.S. client contacts. With 386 recorded shipments, they can share feedback from American bag retailers or distributors.

Guangzhou Senrong Handbag Manufacturing Co., Ltd.

Production Scale: 400 million bags/year | MOQ: Not specified | Lead Time: Flexible based on order volume

Senrong operates on a scale most factories can’t match. Their 26,000 m² dual-factory setup spans Guangzhou and Vietnam. The China facility sits at 5 Heting Middle Road in Baiyun District. That’s right in Guangzhou’s manufacturing core. This two-location strategy gives you production backup. One facility hits capacity? The other picks up overflow.

Product Range Beyond PU Handbags: Senrong excels at custom PU handbags. But they make 15+ bag categories. Cosmetic bags, mommy bags, travel backpacks, cooler bags, and storage solutions all come off their lines. This wide range means their teams know different build methods. Skills move across product types. Your custom PU handbag benefits from techniques they perfected on toiletry bags or canvas totes.

Audit-Proven Quality Systems: Big brands trust Senrong’s quality control. Coca-Cola, Disney, and H&M all audited their facilities. Certifications include BSCI, SGS, SEDEX, plus ISO 9001/14000 standards. Their 5-stage testing covers samples, cutting, screen printing, sewing, and final packing. Each stage catches defects before the next step.

Best For: Large-volume buyers who need solid reliability. Their 400-million-bag annual capacity handles massive orders. Quality stays consistent. Perfect for scaling a successful line or launching multi-SKU collections. The Vietnam facility also gives you tariff options for U.S. imports.

Guangzhou Xianglu Leather Co., Ltd.

Production Scale: 6,584 m² facility | QC Team: 41-50 specialists | Annual Sales: $25-100 Million USD

Xianglu’s reputation comes from solid numbers, not marketing hype. Founded in 2017, this Guangzhou manufacturer earned a perfect 5.0/5.0 Alibaba supplier rating in eight years. They hit 100% on-time delivery across every shipment type. This isn’t a lucky streak—it’s consistent performance.

Quality Control Infrastructure: The pu bag factory assigns 41-50 full-time staff to quality checks. That means one QC person for every 130 square meters of production space. This ratio beats industry standards. Most mid-size factories use 20-30 QC staff for the same floor space. Xianglu catches defects at multiple production stages. They don’t wait until final inspection.

Responsiveness Drives Client Retention: Response time averages under three hours. Send technical questions at 9 AM Beijing time? You get detailed answers before lunch. This speed helps you finish samples faster. It also fixes order issues across time zones. Their 16% reorder rate shows clients return after first orders.

Best For: Brands that value supplier reliability over the lowest price. Their perfect delivery record and fast communication help businesses where missed deadlines mean lost retail space or delayed e-commerce launches.

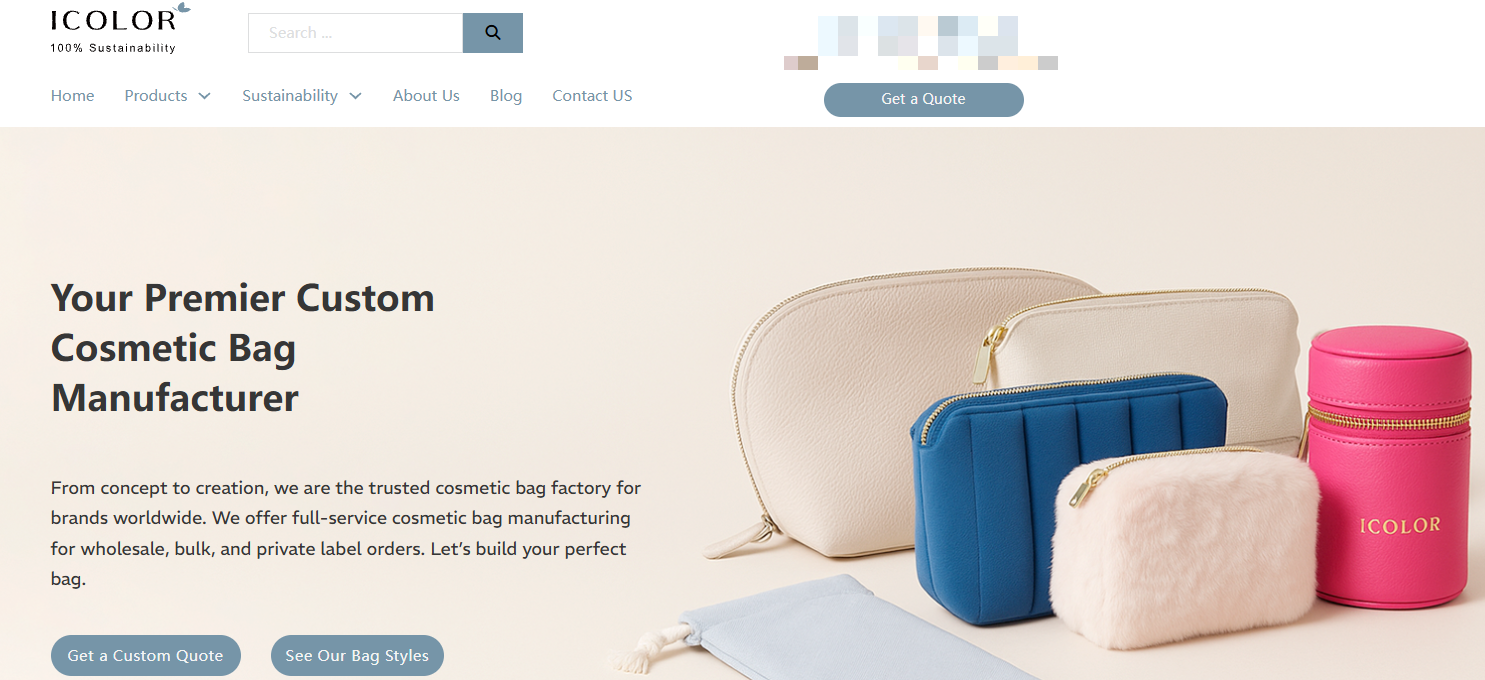

Dongguan Icolor Bag Co., Ltd.

Production Scale: 3,000 m² BSCI-certified facility | Founded: 2018 | Location: Fenggang Town, Dongguan (near Yantian Port)

Icolor focuses on what most PU handbag makers ignore—luxury cosmetic bags and sustainable fashion accessories. They started in 2018. By now, they’ve reached #3 among China’s sustainable cosmetic bag makers. Yiwu Runhui and Rivta rank higher. They also cracked the top 10 for cosmetic cases nationwide. That’s fast growth for a seven-year-old factory.

Design Philosophy Drives Premium Positioning: Icolor’s design team doesn’t just chase trends—they explore them. Each product balances function with visual appeal. Original designs target high-end buyers who want unique pieces, not catalog copies. Their cosmetic bag designs bring luxury brand looks into PU materials. You get the premium look without genuine leather costs.

Product Range Expansion: PU cosmetic bags remain their core strength. But Icolor has expanded into travel bags, storage solutions, folding bags, promotional gift items, and jewelry pouches. Full OEM/ODM customization runs across every category. Corporate branding projects? Event giveaways? Personalized storage? They handle it all. This cross-category skill means your custom PU handbag benefits from techniques perfected on makeup pouches or luggage tags.

Verification Tip: Request samples from their luxury cosmetic bag line. Compare material quality and finishing details against your current suppliers. Their sustainability claims should come with material certifications you can verify on your own.

Yiwu Runhui Bag Co., Ltd.

Production Scale: 37,797 m² facility | MOQ: From 10 pieces | Response Time: Under 2 hours

Runhui stands out with numbers that matter to serious buyers. This Yiwu maker runs China’s largest single-location facility among the top 5 custom PU handbag producers. Their 37,797 square meters dwarf typical mid-size factories. Twenty production lines operate at once. That’s backed by 215 specialized machines and 20 full-time QA/QC inspectors checking every stage.

Best For: Startups testing market demand with small batches. Also fits established brands needing a reliable partner for ongoing collections. The 10-piece MOQ lets you test designs before big bag production runs. Multi-language support (English, Japanese, plus 50+ languages on their website) removes communication barriers for global buyers.

Verification Tip: Request their best-selling cosmetic bag samples—the ones with 2,000+ verified sales. Compare pricing, finishing quality, and material specs against your current suppliers. Their track record on those high-volume items shows what consistency looks like at scale.

Conclusion

The right partner among China’s top 5 custom PU handbag makers can change your product line. It also boosts your market position. Each maker on this list has unique strengths. MTC Bags leads in design innovation. Senrong offers quality certifications. Xianglu excels in material know-how. Icolor specializes in color custom options. Runhui gives competitive prices for smaller orders.

Success comes from matching your needs with the right maker’s skills. First, define your minimum order amounts. Set your quality standards. List your timeline needs. Then, contact 2-3 makers from this list. Send them detailed specs to compare quotes and samples.

The best partnerships go beyond price. Look for makers who show clear communication. Check for open processes. Make sure they understand your target market. Ask for sample products. Verify their certifications. Ask for client references too.

Your next step? Contact at least two makers today with your first inquiry. Start the vetting process now. This helps you find your ideal partner faster. You’ll bring your custom PU handbag vision to life sooner.

Recent Comments