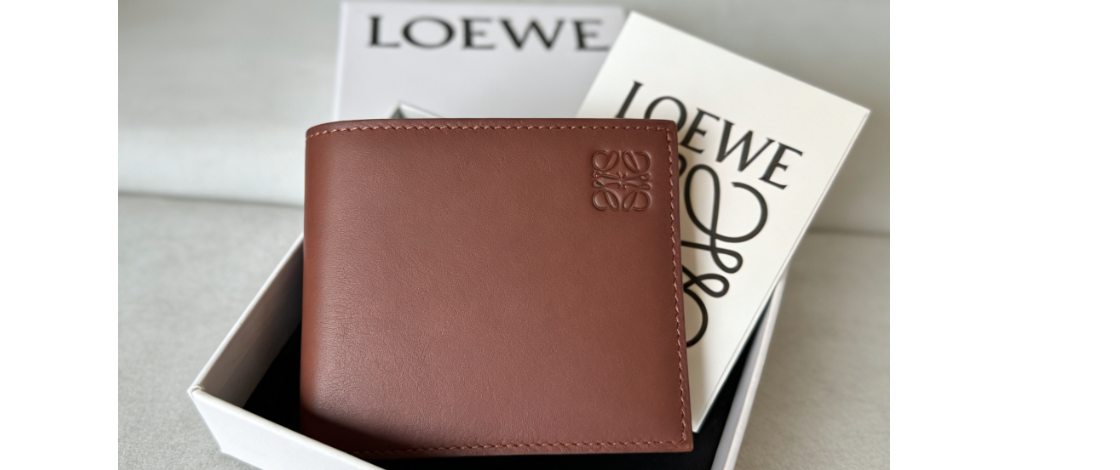

When you pick up a LOEWE genuine leather wallet, you will be overwhelmed by its texture.

But do you know the other side of it? Traditional Spanish craftsmanship is alive and well. The reality of the supply chain is more complex than it seems.

“All Loewe wallets are made in our own atelier in Madrid” – many people believe. There are actually different manufacturing models.

Buyers who are considering OEM OEM. Consumers who want to know how to distinguish the real thing. Those who are interested in the business model of luxury wallet brands. This article is for you.

We will tell you the actual situation of LOEWE genuine leather wallet OEM. These workshops have advanced technology. We will also explain the manufacturing standards that achieve LOEWE quality.

We interviewed industry insiders. We will deliver information based on these.

The truth of manufacturing that luxury brands do not disclose. I will clarify it here.

Loewe Wallet Manufacturing: The Truth About Our Atelier vs. Leather Wallet OEM

Loewe-wallet made models are different from other luxury brands.

Leather wallet manufacturing system centered on our own atelier

Loewe is at the heart of its manufacturing in its own atelier, located next to its headquarters in Madrid. Here, Loewe craftsmen finish each product by hand. This system strictly controls the standards of LLOEWE craftsmanship.

The artisans who work in the ateliers in Madrid have an average of more than 15 years of experience. Loewe inherits the traditional handmade techniques. In wallet manufacturing, one craftsman is in charge of everything from sewing to finishing. This is the common practice.

Limited Leather Wallet OEM Utilization

Loewe does not rely on OEM manufacturing. However, for some of its products we collaborate with small workshops specializing in Spanish leather wallets. These workshops are only available within Loewe Spain. We have passed strict quality standards.

Contracts with OEM workshops include the obligation to use Loewe leather. We provide detailed manuals, from leather cutting methods to sewing techniques. Regular audits ensure that we maintain LOEWE quality standards.

Features of Leather Wallet OEM Quality Assurance System

LOEWE: The most important point to distinguish authenticity is the transparency of the manufacturing process. All wallets are engraved with the serial number. Traceability is ensured. This transparency in the manufacturing process of luxury brands underpins brand value.

Details of our atelier in Madrid, Spain

Loewe Madrid’s own atelier is located near Serrano Street in the city of Madrid. Since its founding in 1846, it has kept its tradition alive and preserved. Approximately 180 Loewe craftsmen currently work. 40% of them specialize in the production of wallets and accessories.

Atelier structure and working environment

The building is a three-story independent workshop. The first floor is the inspection and storage area of Loewe leather. The second floor is a cutting and sewing area. The third floor is the finishing and quality inspection area. We have adopted a vertical division of labor system.

It is designed to let in plenty of natural light. The environment is in place where you can accurately judge the color and texture of the leather.

Each workbench has its own temperature and humidity management system. This is to ensure that the leather is in optimal condition, which determines the quality of Spanish wallets. The room temperature is 18-22 ° C. Humidity is constantly maintained at 45-55%.

Craftsman training system

New craftsmen undergo a minimum of 5 years of training. After that, he was involved in the production of products for the first time.

For the first two years, you will only be responsible for sorting and cutting leather. From the third year, they begin to learn sewing techniques. The inheritance of LOEWE handmade technology is supported by a thorough step-by-step education.

There are only 10 senior craftsmen called master craftsmen. They will conduct the final quality inspection of LOEWE craftsmanship. As a token of LOEWE’s authenticity, the master craftsman’s personal engraving is applied to the inside of the product.

Manufacturing capacity and production number

The monthly production capacity of the Madrid Atelier is approximately 8,000 wallets. All luxury brands are manufactured under the strict standards of the manufacturing process.

It takes an average of 12-15 hours to complete a wallet. Complex designs can exceed 20 hours.

Loewe Leather Wallet OEM Manufacturing Process and Quality Control

At the manufacturing site of LOEWE genuine leather wallet OEM, 11 steps are carried out sequentially. Each process has its own quality standards.

From leather sorting to cutting

Only the highest quality calfskin is used for raw skin. It is carefully selected for its smoothness of the surface and the characteristic aroma of leather. Pigments and dyes are sorted and toned before cutting. Adjust the gloss with a unique formula of processing agent. This stage gives rise to the characteristic texture of Loewe leather.

In cutting, the craftsman determines the direction of the leather fibers. You can only take up to 5 wallet parts from a single piece of leather. The yield rate is 40-45%. This is lower than the industry average of 60%, but to maintain quality.

Technical standards for sewing and fittings

Loewe handmade sewing uses thicker threads. The stitch spacing is uniform to 2.5 mm or less. On average, more than 300 stitches are hand-sewn on one wallet. The seams should be straight and even, with zero fraying as an absolute condition.

All metal fittings have smooth and uniform plating treatment. Glossy is ensured up to the edges. The zipper is made of YKK sliders. Some Loewe genuine leather wallet OEM workshops also use the same specifications.

Precision technology for cobalting

The cross-sectional treatment of leather (edge coating) is a process that symbolizes Loewe craftsmanship. Edge processing by hand painting is carried out. Apply 4-6 layers with a special black and brown paint.

Fine uneven coating occurs due to manual work. This is what makes LOEWE real. The strap and handle part have a larger paint area. Therefore, a slight fluid residue may be observed. According to the LOEWE quality standard, if the thickness is uneven within 0.2 mm, it passes.

Anagram imprinting and final inspection

Embossing engraves a three-dimensional line with four L’s elaborately combined. Continuous pattern or single engraving on smooth leather. Embossing must be uneven and have a careful finish. If the line is tilted or uneven, it will be rejected immediately.

Engrave 8-10 digits of model ID on the inside of the product. The tags on storage bags are also subject to inspection. Make sure the logo line is printed straight and neatly. The final inspection by the master craftsman carefully checks the texture of the genuine leather. We will take a closer look at whether there is any print peeling or matte surface like synthetic leather.

Why luxury brands use leather wallet OEMs and Loewe’s strategy

It’s clear why luxury brands use OEM. Because it is economically reasonable. By choosing not to have your own factory, you can significantly reduce your initial investment. It can reduce capital expenditure costs. This is a strategy that focuses resources on planning and branding.

Cost Optimization and Risk Management for Leather Wallet OEMs

With the technology of professional manufacturers, you can ensure stable and high quality. It can also handle small batch production. Reduce the risk of overstocking.

The profit margin of OEM utilization ranges from 10-50% in the field. We have achieved high profit margins in high-value-added fields such as cosmetics. The same goes for Loewe genuine leather wallet OEM. Reduce manufacturing costs. At the same time, it maintains a high brand value.

Strategic Value of Leather Wallet OEM

Genuine leather wallets are products that can maximize the expressiveness of high-quality materials. It can take advantage of the large surface area. It highlights the beauty of materials such as Venetian leather. It has the characteristic of increasing its luster and depth over time. This is another important component of the customer experience.

The creation of psychological value cannot be overlooked. The wallet acts as a status symbol. Take a look at the survey data. Superiority over others increased by 14 points from 37.4% to 51.4%. It is increasingly serving as a symbol of self-expression.

Loewe’s Differentiation Strategy

Loewe Spain’s strategy is simple. It is to ensure consistent quality control even though it is an OEM. Let’s take a look at Berluti’s case. Long wallet OEM is entirely made of Venetian leather. Achieved a painting-like dyeing gradient. Even the deterioration process is valued as beauty.

Loewe has the same approach. Loewe Craftsmanship is staged. Visualize craftsmanship. This justifies the premium price. There is a worldview construction such as Hermès’ hand-sewn and Louis Vuitton’s travel art. Customers are convinced of high payments.

How to Find a LOEWE Quality Level Leather Wallet OEM Factory

Selecting an OEM factory for luxury leather products requires a clear evaluation axis. To find a manufacturing partner that matches LOEWE’s wallet quality, there are three specific points of verification:

Confirmation of integrated production system

A reliable OEM factory centrally manages material procurement and manufacturing within the factory. Take a look at the case of Ogura Meriyasu Factory. We produce fabrics, materials, patterns, sewing, and post-processing in an integrated manner. This achieves quality traceability at the level of Loewe leather.

At the Tochigi Sano Factory, small lots are also available. Domestic production demand increased in the five years before the pandemic. Partnerships with DtoC brands are expanding. Until 2008, I was doing post-processing in Tokyo and sewing in Tochigi. Now all functions are consolidated in Tochigi. Both production efficiency and quality control have been improved.

Benchmarking material quality

Choose a factory that uses calfskin as standard for 6 months of age. The fibers are fine and soft to the touch. It meets the standards of LOEWE genuine leather wallet OEM.

The Crocodile Leather OEM Workshop in Thailand is a good example. The long-established workshop has been conducting OEM leather wallet production for many years to meet the quality standards of foreign brands. We have shortened the manufacturing and distribution process. We can provide high quality at a low price.

Evaluate the factory’s management philosophy

The technology of the China ASEAN sewing factory has made great progress in 10 years. We have introduced machines made in Japan. The superiority in terms of quality is declining.

The key to differentiation is the philosophy of the factory. Check out our commitment to environmental activities. We also check our attitude towards sustainability. This is the differentiating point of Japan. Luxury brands in the manufacturing process require a shared share of this value.

Summary: Loewe’s true value and implications for the leather wallet OEM market

We investigated the actual situation of manufacturing Loewe genuine leather wallets. One important truth has been revealed. Loewe is based on handmade production in its own atelier in Madrid. At the same time, we have partnerships with selected artisan workshops in Spain. In these two ways, we maintain unparalleled quality.

There is something we can learn from this survey. A true luxury brand is not just a binary of in-house production or outsourcing. Strict quality standards and the inheritance of craftsmanship are the essence. Traditional Andalusian leather workshops play an important role. As one of the few OEM partners capable of delivering Loewe-level quality, we support the global luxury market.

Are you looking for OEM manufacturing of high-quality genuine leather products? Do you want to incorporate Loewe-class craftsmanship into your products? Please feel free to contact SUNTEAMOEM. Discover a reliable partner workshop that meets Spanish manufacturing standards. We also support you in building quality control processes. We will help you in total.

True craftsmanship is not in the brand logo. It dwells in every needle.

Recent Comments